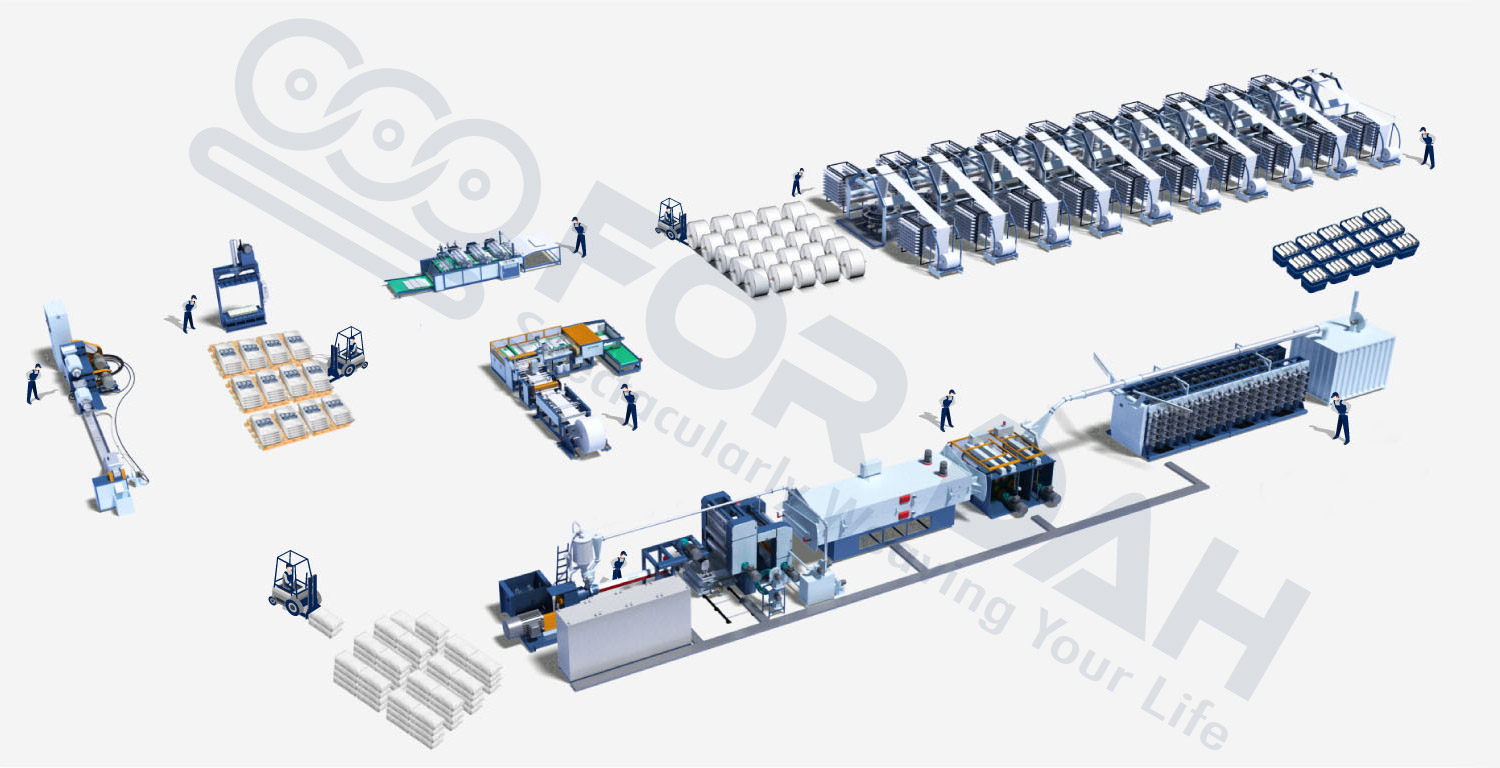

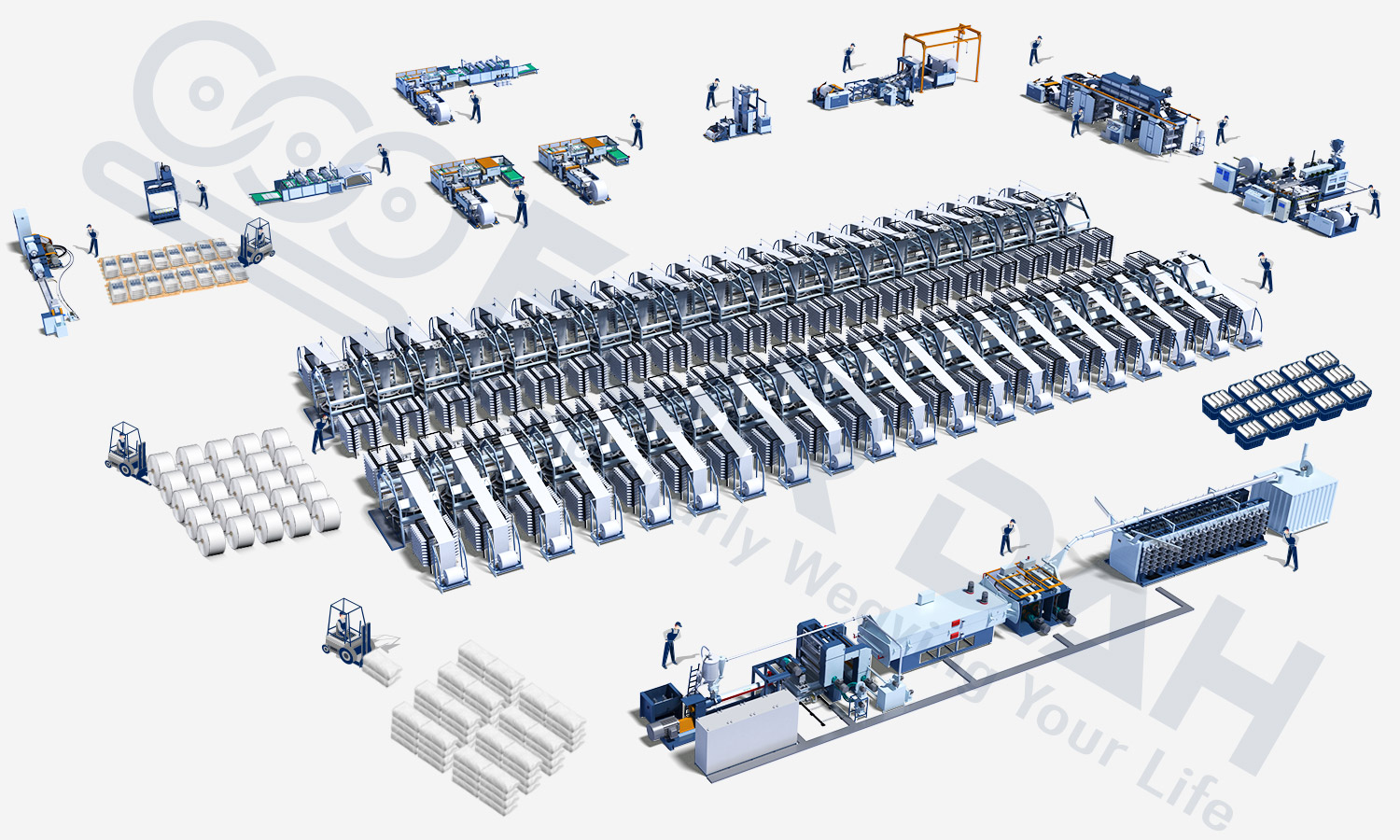

PP/HDPE Woven Bag

Complete line solutions. Optimise the costs and performance of your line.

-

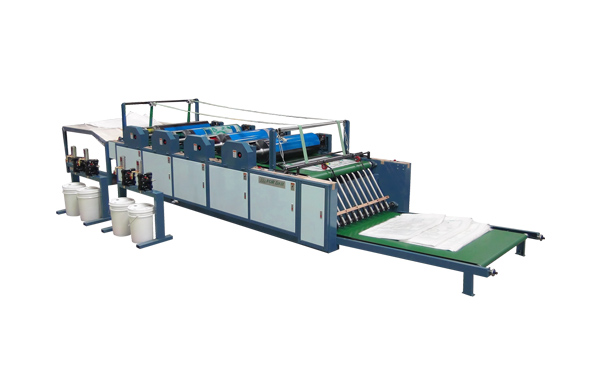

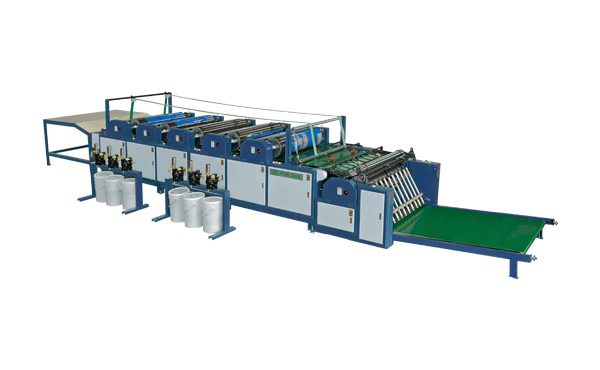

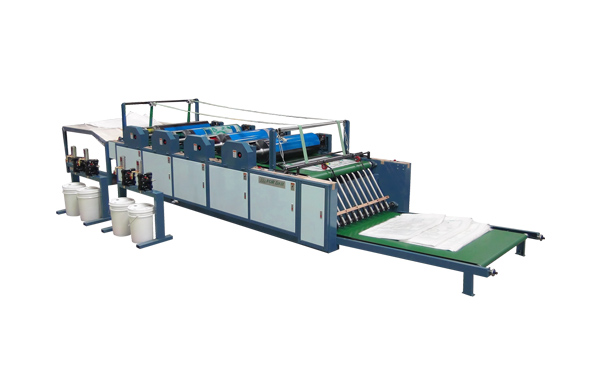

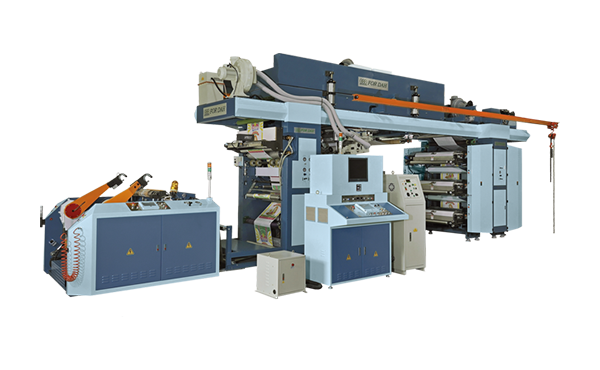

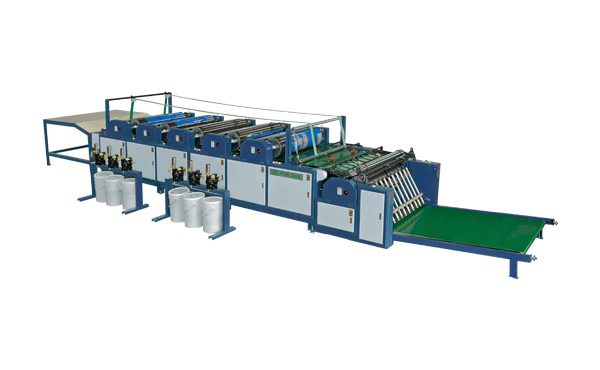

E400 SeriesSingle Side 2~6 Color Piece to Piece Printing Machine -Horizontal Feeding (Direct Printing)

The bag will be fed by horizontal direction. Our single side 2~6 color piece to piece printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination, it is suitable for ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

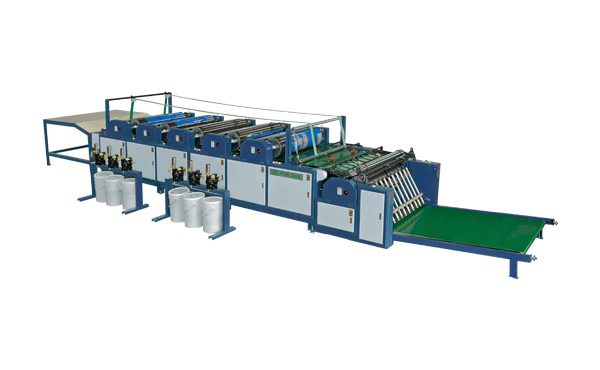

ED400 SeriesDouble Side 3~6 Color Piece to Piece Printing Machine (Direct Printing)

It is available for double side printing. The double side 3~6 color piece to piece printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination, it is suitable for double side ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

H400 SeriesSingle 2~6 Color Piece to Piece Printing Machine -Vertical Feeding (Direct Printing)

The bag will be fed by vertical direction. The single 2~6 color piece to piece printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination, it is suitable for ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

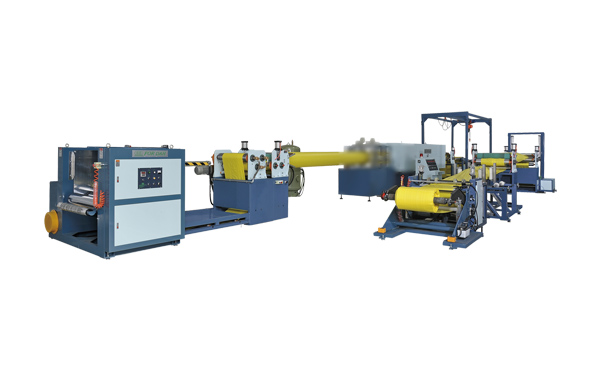

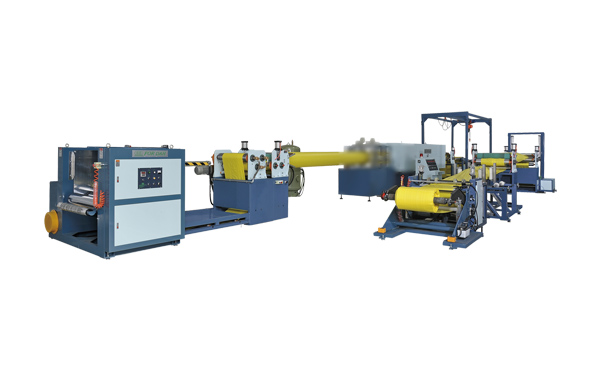

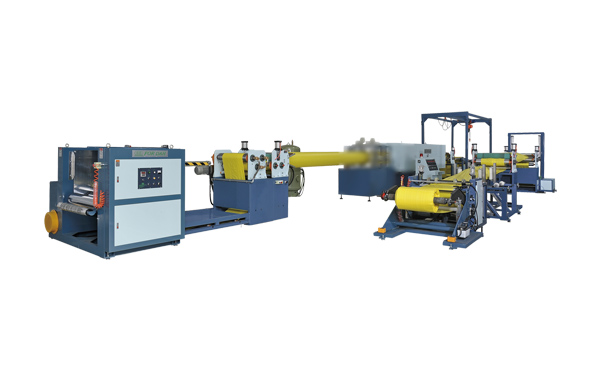

FD-LA75(S) & FD-LA90(S) & FD-LA100(S)Single Side by Turn Bar and Outside Lamination Machine

The single side by turn bar and outside lamination machine are used for coating of thin layer of Polyolefin (mainly LDPE/PP) on substrates like woven fabric, BOPP film, paper, jumbo bag (FIBC) etc, which is for moisture-proof, dust-proof, and structurally strong enough.

-

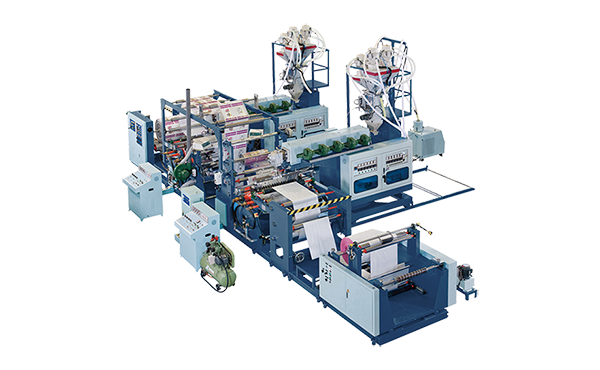

FD-LA75(D) & FD-LA90(D) & FD-LA100(D)Double Side and Outside LDPE/PP Lamination Machine

The double side and outside LDPE/PP lamination machine are used for coating of thin layer of Polyolefin (mainly LDPE/PP) on substrates like woven fabric, BOPP film, paper, jumbo bag (FIBC) etc, which is for moisture-proof, dust-proof, and structurally strong enough.

-

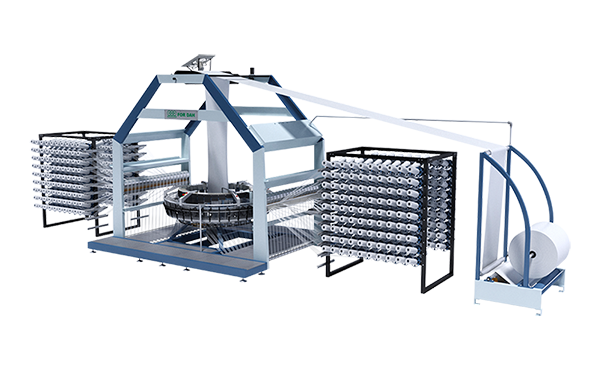

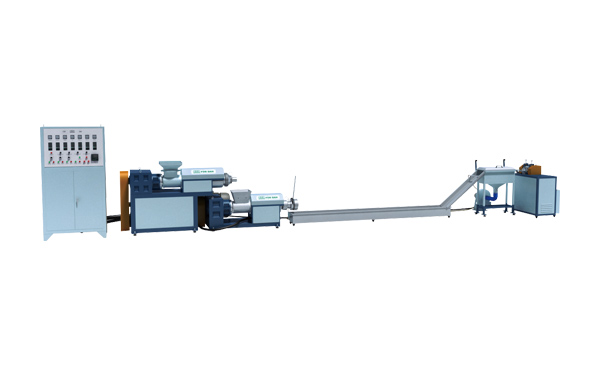

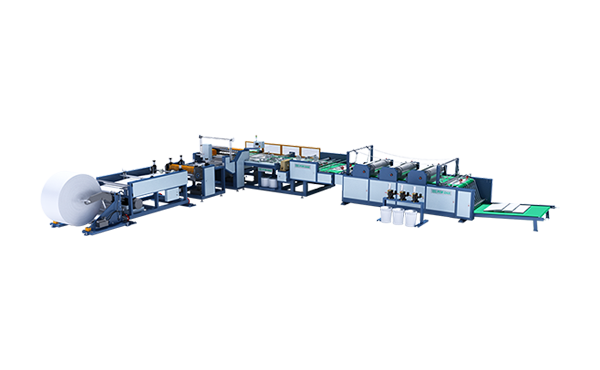

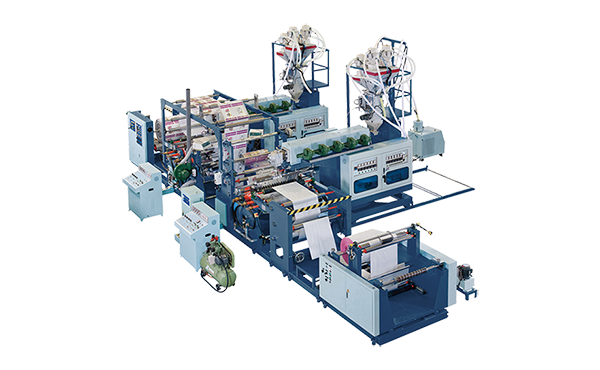

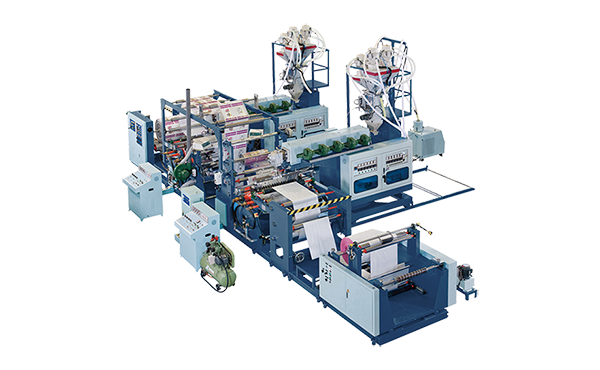

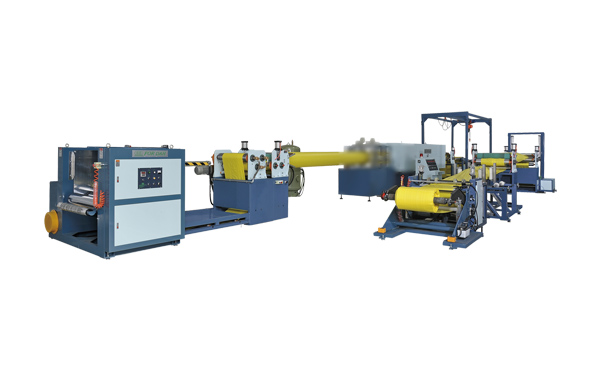

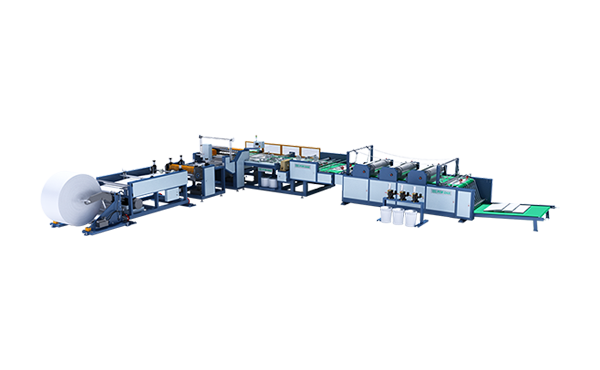

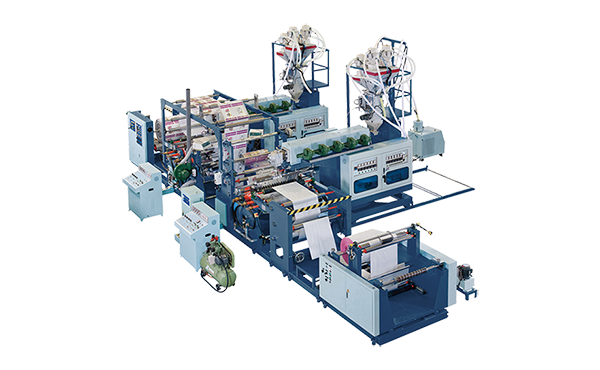

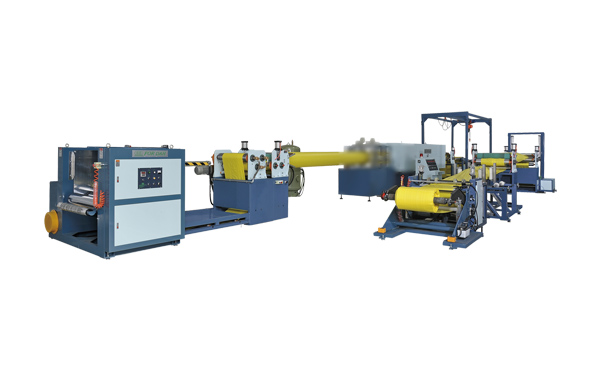

FD-IST-650 + FD-ILM-850Line of PP Tubular Fabric Film Inserting And Inside Lamination Machine

Our PP tubular fabric film inserting and inside lamination machine, combined with the PP Woven Bag Inner Liner Insert Machine, is designed for producing PP woven inside laminating bags by bonding the two-layer liner with outer woven cloth, utilizing a high-quality PP lamination machine. This setup is ideal for waterproof packaging of chemical materials, fertilizers, feed, flour, sugar, fish meal, powder, and more. It offers easy operation and labor-saving automation, increasing production efficiency and minimizing human error.

-

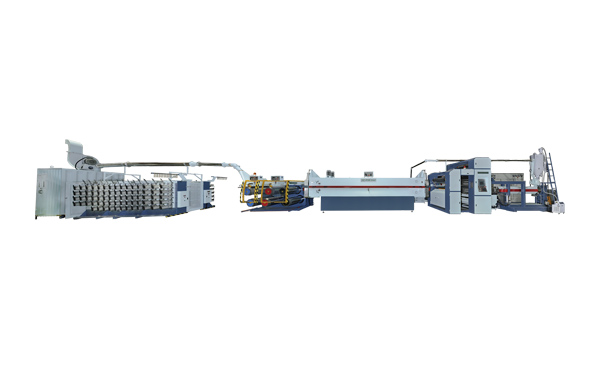

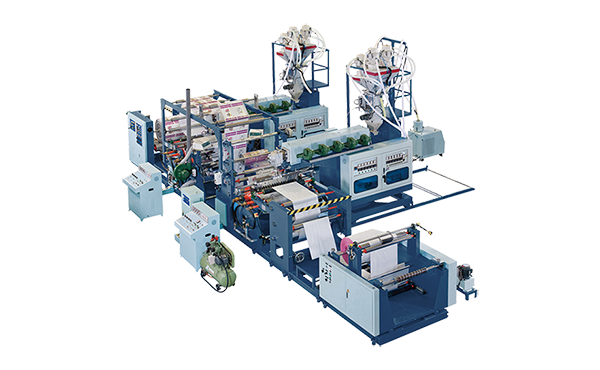

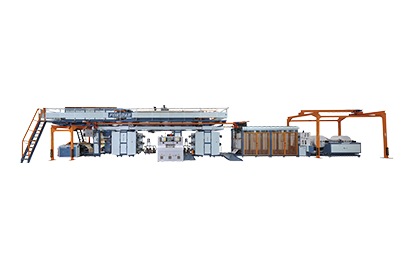

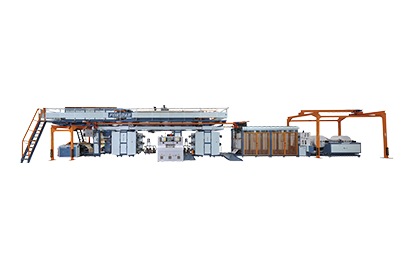

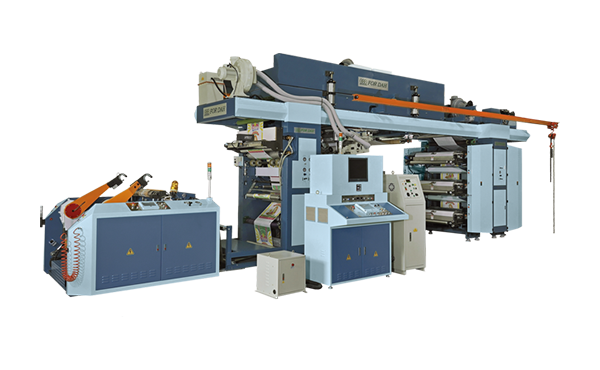

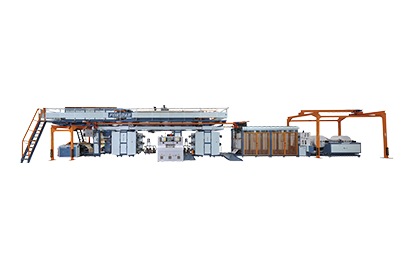

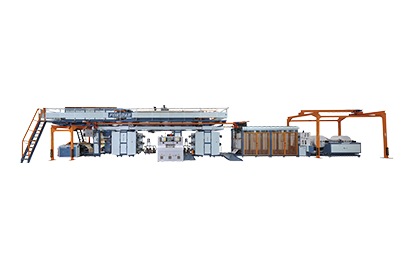

900W series (250M)Flexographic High Speed Roll to Roll 8~12 Color Printing Machine with 2 Printing Stack and 4 Drying Oven (Direct Printing)

Max. machine speed: 250M/Min. Standard including: Additional 2 ovens, CPC, In –feed servo control, Corona treatment, Non-stop Un-winder, Auto. Re-winder & servo control out-feed Our flexographic roll to roll 8~12 color printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination. Available for CMYK color combination to obtain realistic printing quality to enhance packing value. Newly developed printing machine offers max. line speed 250M/Min.

-

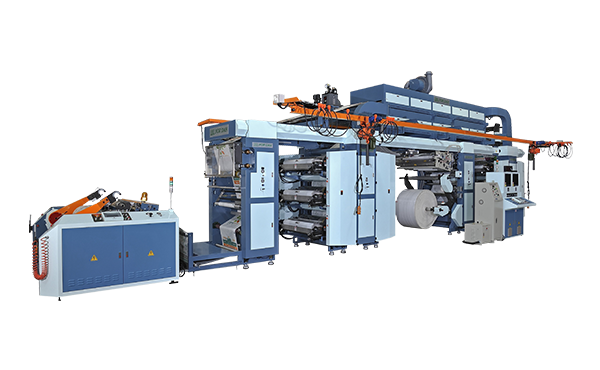

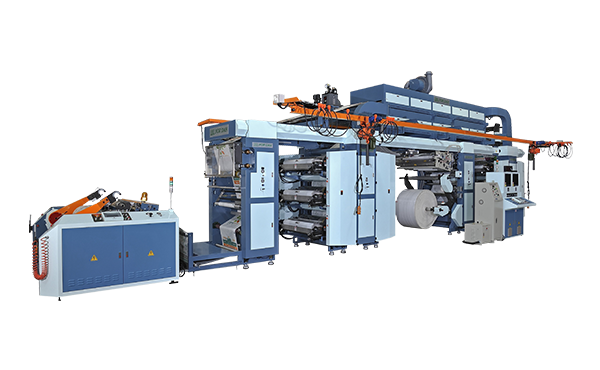

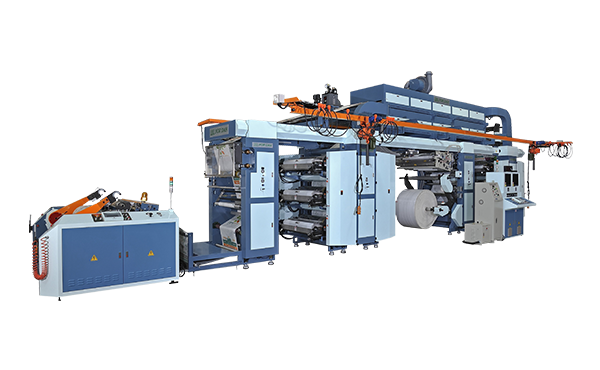

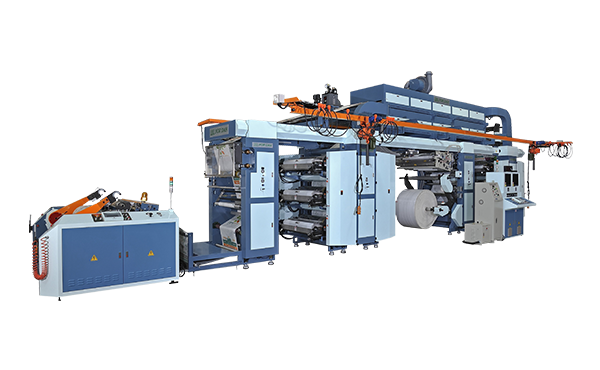

900W series (180M)High Speed Flexographic Printing Machine | Roll to Roll 6~12 Color Direct Printing Machine with 2 Printing Stack

Max. machine speed: 180M/Min. Standard features include: Non-stop Un-winder, Auto Re-winder, out-feed by servo control, and Corona treatment. Our high-speed flexographic printing machine, designed for roll to roll 6~12 color direct printing, is ideal for solvent-based ink applications on PP woven bags, with or without lamination. It supports CMYK color combinations to achieve realistic printing quality, enhancing the packaging value.

-

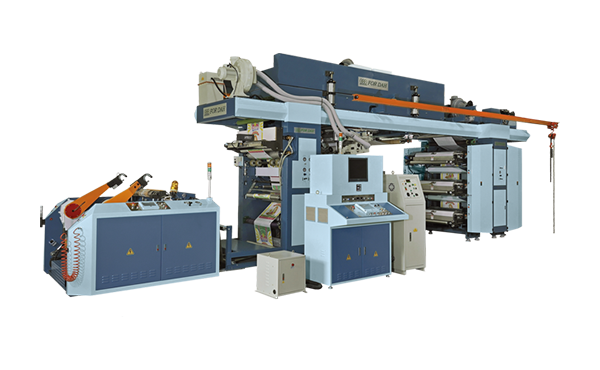

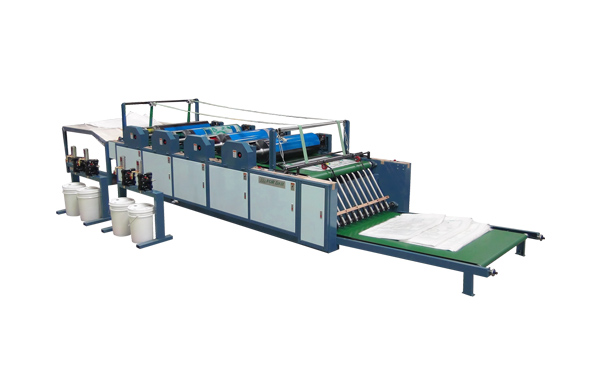

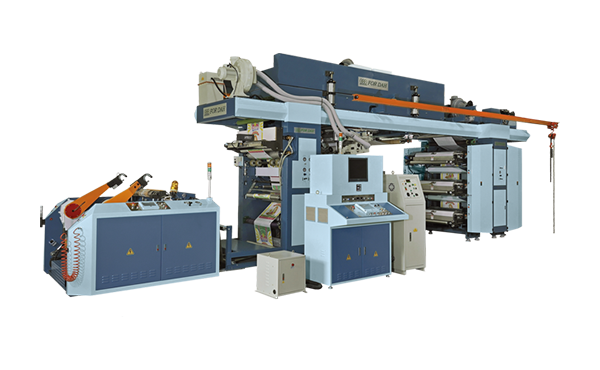

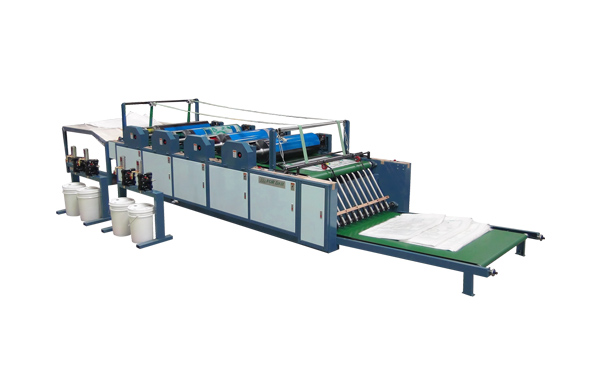

900W Series (120M)Flexographic Roll to Roll 4~6 Color Printing Machine with Single Printing Stack (Direct Printing)

Max. machine speed: 120M/Min. Standard including: Corona treatment The flexographic roll to roll 4~6 color printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination. Available for CMYK color combination to obtain realistic printing quality to enhance packing value.

-

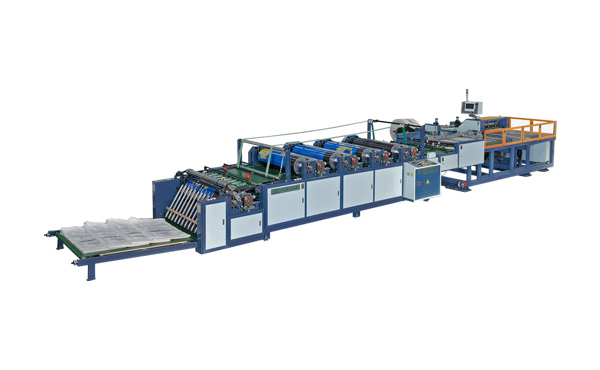

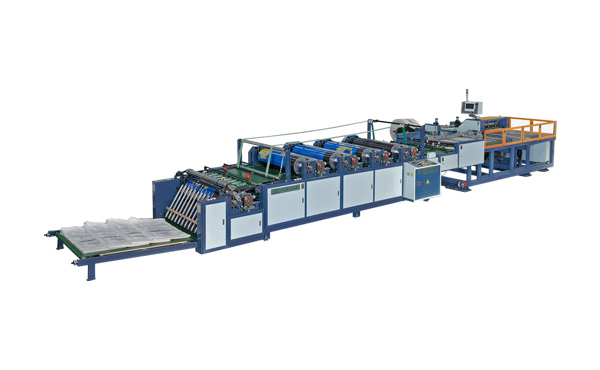

300 SeriesFlexographic Double Side Servo Control 4~9 Color Roll to Roll Printing Machine (Indirect Printing)

Our double side servo control flexographic 4~9 color roll to roll printing machine is applied for solvent-based ink and indirect printing method for PP woven bag with/without lamination, it is suitable for ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

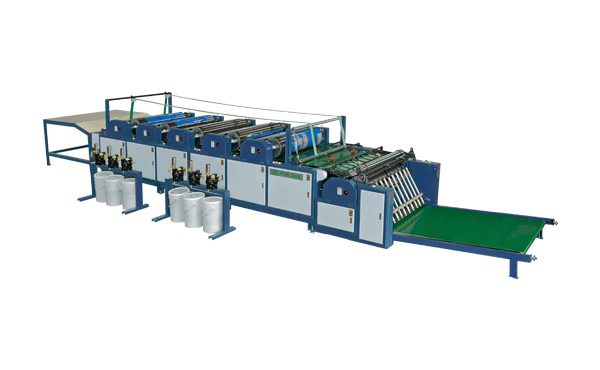

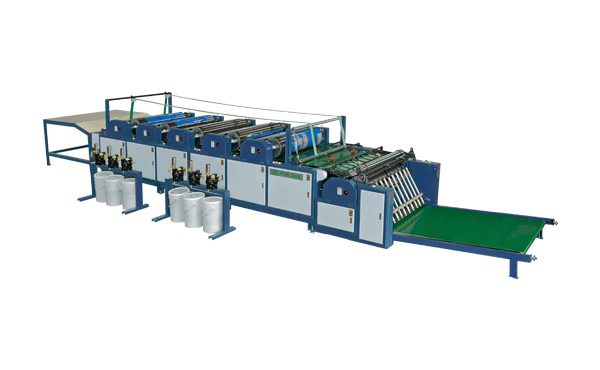

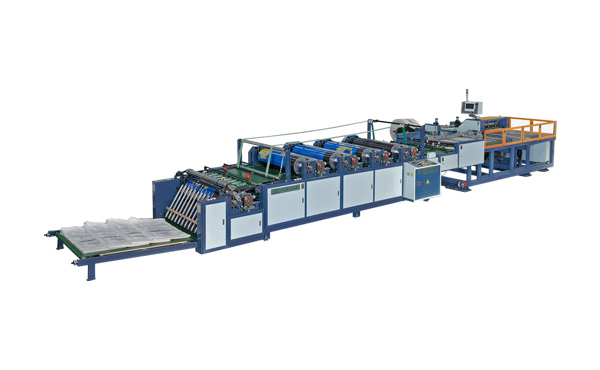

R400 SeriesFlexographic Single Side 4~6 Color Roll to Roll Printing Machine (Direct Printing)

Our single-side 4~6 color roll-to-roll flexographic printing machine is specifically engineered for roll-to-roll printing applications with solvent-based ink. It excels in direct printing without the need to change the plate cylinder, which significantly enhances efficiency and reduces downtime. This machine is particularly well-suited for printing on PP woven bags, whether laminated or unlaminated. With its innovative design and precise CMYK color combination, it ensures exceptional print quality, outperforming traditional piece-to-piece printing methods. Equipped with advanced technology for optimized performance and reliability, our roll-to-roll printing machine boasts user-friendly controls for seamless operation, even for operators with minimal experience. Whether handling large volumes or small batches, it offers unparalleled versatility and durability for any printing operation.

-

GS-80Gusseting & Rotating Machine

The gusseting and rotating machine is designed for making side gusseting and rotating in a roll to roll operation. Available for PP woven bag, laminated woven, and BOPP laminated bag.

-

G-80Gusseting Machine

The gusseting machine is designed for making side gusseting in a roll to roll operation. Available for PP woven bag, laminated woven, and BOPP laminated bag.

-

E400 SeriesSingle Side 2~6 Color Piece to Piece Printing Machine -Horizontal Feeding (Direct Printing)

The bag will be fed by horizontal direction. Our single side 2~6 color piece to piece printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination, it is suitable for ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

ED400 SeriesDouble Side 3~6 Color Piece to Piece Printing Machine (Direct Printing)

It is available for double side printing. The double side 3~6 color piece to piece printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination, it is suitable for double side ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

H400 SeriesSingle 2~6 Color Piece to Piece Printing Machine -Vertical Feeding (Direct Printing)

The bag will be fed by vertical direction. The single 2~6 color piece to piece printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination, it is suitable for ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

FD-LA75(S) & FD-LA90(S) & FD-LA100(S)Single Side by Turn Bar and Outside Lamination Machine

The single side by turn bar and outside lamination machine are used for coating of thin layer of Polyolefin (mainly LDPE/PP) on substrates like woven fabric, BOPP film, paper, jumbo bag (FIBC) etc, which is for moisture-proof, dust-proof, and structurally strong enough.

-

FD-LA75(D) & FD-LA90(D) & FD-LA100(D)Double Side and Outside LDPE/PP Lamination Machine

The double side and outside LDPE/PP lamination machine are used for coating of thin layer of Polyolefin (mainly LDPE/PP) on substrates like woven fabric, BOPP film, paper, jumbo bag (FIBC) etc, which is for moisture-proof, dust-proof, and structurally strong enough.

-

FD-IST-650 + FD-ILM-850Line of PP Tubular Fabric Film Inserting And Inside Lamination Machine

Our PP tubular fabric film inserting and inside lamination machine, combined with the PP Woven Bag Inner Liner Insert Machine, is designed for producing PP woven inside laminating bags by bonding the two-layer liner with outer woven cloth, utilizing a high-quality PP lamination machine. This setup is ideal for waterproof packaging of chemical materials, fertilizers, feed, flour, sugar, fish meal, powder, and more. It offers easy operation and labor-saving automation, increasing production efficiency and minimizing human error.

-

900W series (250M)Flexographic High Speed Roll to Roll 8~12 Color Printing Machine with 2 Printing Stack and 4 Drying Oven (Direct Printing)

Max. machine speed: 250M/Min. Standard including: Additional 2 ovens, CPC, In –feed servo control, Corona treatment, Non-stop Un-winder, Auto. Re-winder & servo control out-feed Our flexographic roll to roll 8~12 color printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination. Available for CMYK color combination to obtain realistic printing quality to enhance packing value. Newly developed printing machine offers max. line speed 250M/Min.

-

900W series (180M)High Speed Flexographic Printing Machine | Roll to Roll 6~12 Color Direct Printing Machine with 2 Printing Stack

Max. machine speed: 180M/Min. Standard features include: Non-stop Un-winder, Auto Re-winder, out-feed by servo control, and Corona treatment. Our high-speed flexographic printing machine, designed for roll to roll 6~12 color direct printing, is ideal for solvent-based ink applications on PP woven bags, with or without lamination. It supports CMYK color combinations to achieve realistic printing quality, enhancing the packaging value.

-

900W Series (120M)Flexographic Roll to Roll 4~6 Color Printing Machine with Single Printing Stack (Direct Printing)

Max. machine speed: 120M/Min. Standard including: Corona treatment The flexographic roll to roll 4~6 color printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination. Available for CMYK color combination to obtain realistic printing quality to enhance packing value.

-

300 SeriesFlexographic Double Side Servo Control 4~9 Color Roll to Roll Printing Machine (Indirect Printing)

Our double side servo control flexographic 4~9 color roll to roll printing machine is applied for solvent-based ink and indirect printing method for PP woven bag with/without lamination, it is suitable for ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

R400 SeriesFlexographic Single Side 4~6 Color Roll to Roll Printing Machine (Direct Printing)

Our single-side 4~6 color roll-to-roll flexographic printing machine is specifically engineered for roll-to-roll printing applications with solvent-based ink. It excels in direct printing without the need to change the plate cylinder, which significantly enhances efficiency and reduces downtime. This machine is particularly well-suited for printing on PP woven bags, whether laminated or unlaminated. With its innovative design and precise CMYK color combination, it ensures exceptional print quality, outperforming traditional piece-to-piece printing methods. Equipped with advanced technology for optimized performance and reliability, our roll-to-roll printing machine boasts user-friendly controls for seamless operation, even for operators with minimal experience. Whether handling large volumes or small batches, it offers unparalleled versatility and durability for any printing operation.

-

GS-80Gusseting & Rotating Machine

The gusseting and rotating machine is designed for making side gusseting and rotating in a roll to roll operation. Available for PP woven bag, laminated woven, and BOPP laminated bag.

-

G-80Gusseting Machine

The gusseting machine is designed for making side gusseting in a roll to roll operation. Available for PP woven bag, laminated woven, and BOPP laminated bag.

-

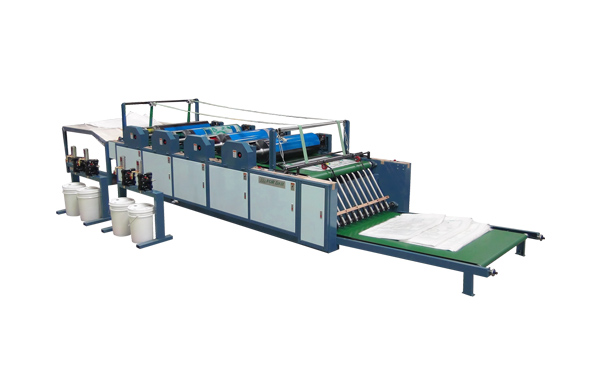

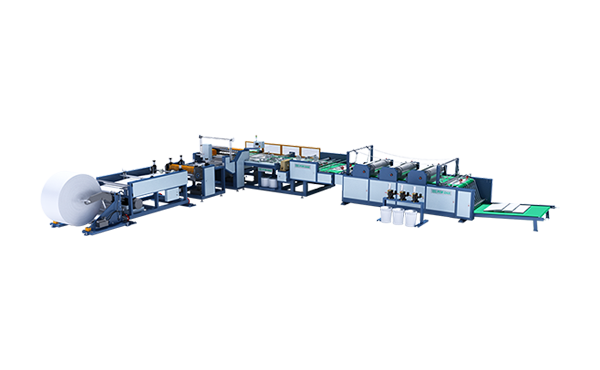

500-3C SeriesAuto. Cutting, Sewing and Single Side 2~6 Printing Machine

Our automatic cutting, sewing and single side 2~6 printing machine is the combination of auto. cutting & sewing machine and single side printing machine to be online operation to perform a ready bag. With auto. online working process ensures the saving of labor with productive capacity.

-

ED600-3C SeriesAuto. Cutting, Sewing and Double Side 2~6 Printing Machine

It is the combination of auto. cutting & sewing machine and double side printing machine to be online operation to perform a ready bag. With auto. online working process ensures the saving of labor with productive capacity.

-

E400 SeriesSingle Side 2~6 Color Piece to Piece Printing Machine -Horizontal Feeding (Direct Printing)

The bag will be fed by horizontal direction. Our single side 2~6 color piece to piece printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination, it is suitable for ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

ED400 SeriesDouble Side 3~6 Color Piece to Piece Printing Machine (Direct Printing)

It is available for double side printing. The double side 3~6 color piece to piece printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination, it is suitable for double side ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

H400 SeriesSingle 2~6 Color Piece to Piece Printing Machine -Vertical Feeding (Direct Printing)

The bag will be fed by vertical direction. The single 2~6 color piece to piece printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination, it is suitable for ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

FD-LA75(S) & FD-LA90(S) & FD-LA100(S)Single Side by Turn Bar and Outside Lamination Machine

The single side by turn bar and outside lamination machine are used for coating of thin layer of Polyolefin (mainly LDPE/PP) on substrates like woven fabric, BOPP film, paper, jumbo bag (FIBC) etc, which is for moisture-proof, dust-proof, and structurally strong enough.

-

FD-LA75(D) & FD-LA90(D) & FD-LA100(D)Double Side and Outside LDPE/PP Lamination Machine

The double side and outside LDPE/PP lamination machine are used for coating of thin layer of Polyolefin (mainly LDPE/PP) on substrates like woven fabric, BOPP film, paper, jumbo bag (FIBC) etc, which is for moisture-proof, dust-proof, and structurally strong enough.

-

FD-IST-650 + FD-ILM-850Line of PP Tubular Fabric Film Inserting And Inside Lamination Machine

Our PP tubular fabric film inserting and inside lamination machine, combined with the PP Woven Bag Inner Liner Insert Machine, is designed for producing PP woven inside laminating bags by bonding the two-layer liner with outer woven cloth, utilizing a high-quality PP lamination machine. This setup is ideal for waterproof packaging of chemical materials, fertilizers, feed, flour, sugar, fish meal, powder, and more. It offers easy operation and labor-saving automation, increasing production efficiency and minimizing human error.

-

900W series (250M)Flexographic High Speed Roll to Roll 8~12 Color Printing Machine with 2 Printing Stack and 4 Drying Oven (Direct Printing)

Max. machine speed: 250M/Min. Standard including: Additional 2 ovens, CPC, In –feed servo control, Corona treatment, Non-stop Un-winder, Auto. Re-winder & servo control out-feed Our flexographic roll to roll 8~12 color printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination. Available for CMYK color combination to obtain realistic printing quality to enhance packing value. Newly developed printing machine offers max. line speed 250M/Min.

-

900W series (180M)High Speed Flexographic Printing Machine | Roll to Roll 6~12 Color Direct Printing Machine with 2 Printing Stack

Max. machine speed: 180M/Min. Standard features include: Non-stop Un-winder, Auto Re-winder, out-feed by servo control, and Corona treatment. Our high-speed flexographic printing machine, designed for roll to roll 6~12 color direct printing, is ideal for solvent-based ink applications on PP woven bags, with or without lamination. It supports CMYK color combinations to achieve realistic printing quality, enhancing the packaging value.

-

900W Series (120M)Flexographic Roll to Roll 4~6 Color Printing Machine with Single Printing Stack (Direct Printing)

Max. machine speed: 120M/Min. Standard including: Corona treatment The flexographic roll to roll 4~6 color printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination. Available for CMYK color combination to obtain realistic printing quality to enhance packing value.

-

300 SeriesFlexographic Double Side Servo Control 4~9 Color Roll to Roll Printing Machine (Indirect Printing)

Our double side servo control flexographic 4~9 color roll to roll printing machine is applied for solvent-based ink and indirect printing method for PP woven bag with/without lamination, it is suitable for ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

R400 SeriesFlexographic Single Side 4~6 Color Roll to Roll Printing Machine (Direct Printing)

Our single-side 4~6 color roll-to-roll flexographic printing machine is specifically engineered for roll-to-roll printing applications with solvent-based ink. It excels in direct printing without the need to change the plate cylinder, which significantly enhances efficiency and reduces downtime. This machine is particularly well-suited for printing on PP woven bags, whether laminated or unlaminated. With its innovative design and precise CMYK color combination, it ensures exceptional print quality, outperforming traditional piece-to-piece printing methods. Equipped with advanced technology for optimized performance and reliability, our roll-to-roll printing machine boasts user-friendly controls for seamless operation, even for operators with minimal experience. Whether handling large volumes or small batches, it offers unparalleled versatility and durability for any printing operation.

-

GS-80Gusseting & Rotating Machine

The gusseting and rotating machine is designed for making side gusseting and rotating in a roll to roll operation. Available for PP woven bag, laminated woven, and BOPP laminated bag.

-

G-80Gusseting Machine

The gusseting machine is designed for making side gusseting in a roll to roll operation. Available for PP woven bag, laminated woven, and BOPP laminated bag.

-

FD-LA75(S) & FD-LA90(S) & FD-LA100(S)Single Side by Turn Bar and Outside Lamination Machine

The single side by turn bar and outside lamination machine are used for coating of thin layer of Polyolefin (mainly LDPE/PP) on substrates like woven fabric, BOPP film, paper, jumbo bag (FIBC) etc, which is for moisture-proof, dust-proof, and structurally strong enough.

-

FD-LA75(D) & FD-LA90(D) & FD-LA100(D)Double Side and Outside LDPE/PP Lamination Machine

The double side and outside LDPE/PP lamination machine are used for coating of thin layer of Polyolefin (mainly LDPE/PP) on substrates like woven fabric, BOPP film, paper, jumbo bag (FIBC) etc, which is for moisture-proof, dust-proof, and structurally strong enough.

-

FD-IST-650 + FD-ILM-850Line of PP Tubular Fabric Film Inserting And Inside Lamination Machine

Our PP tubular fabric film inserting and inside lamination machine, combined with the PP Woven Bag Inner Liner Insert Machine, is designed for producing PP woven inside laminating bags by bonding the two-layer liner with outer woven cloth, utilizing a high-quality PP lamination machine. This setup is ideal for waterproof packaging of chemical materials, fertilizers, feed, flour, sugar, fish meal, powder, and more. It offers easy operation and labor-saving automation, increasing production efficiency and minimizing human error.

-

E400 SeriesSingle Side 2~6 Color Piece to Piece Printing Machine -Horizontal Feeding (Direct Printing)

The bag will be fed by horizontal direction. Our single side 2~6 color piece to piece printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination, it is suitable for ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

ED400 SeriesDouble Side 3~6 Color Piece to Piece Printing Machine (Direct Printing)

It is available for double side printing. The double side 3~6 color piece to piece printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination, it is suitable for double side ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

H400 SeriesSingle 2~6 Color Piece to Piece Printing Machine -Vertical Feeding (Direct Printing)

The bag will be fed by vertical direction. The single 2~6 color piece to piece printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination, it is suitable for ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

500-3C SeriesAuto. Cutting, Sewing and Single Side 2~6 Printing Machine

Our automatic cutting, sewing and single side 2~6 printing machine is the combination of auto. cutting & sewing machine and single side printing machine to be online operation to perform a ready bag. With auto. online working process ensures the saving of labor with productive capacity.

-

ED600-3C SeriesAuto. Cutting, Sewing and Double Side 2~6 Printing Machine

It is the combination of auto. cutting & sewing machine and double side printing machine to be online operation to perform a ready bag. With auto. online working process ensures the saving of labor with productive capacity.