High Speed Auto PP Woven Bag Cutting and Sewing Machine

RS-3C

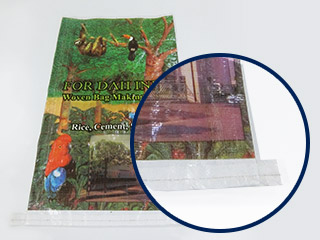

FOR DAH's PP Woven Bag Cutting and Sewing Machine completes the final stage of woven bag production with cutting, bottom folding, sewing, and stacking in a single operation. It supports various types such as BOPP laminated bags, gusseted bags, easy open bags, perforated bags, punched bags, handle bags, double stitching bags, and leno bags. Designed with 4 bag clippers, the machine handles low-denier PP woven bags smoothly for precise feeding and stacking.

Features

- The unwinder is with pneumatic pedal device to lift the fabric roll easily without any mechanical tools.

- The cloth feeding is driven by dancing roller to maintain uniform tension of the fabric.

- Dual servo control for cloth feeding and bag clamping helps minimize the cutting length variation.

- The clipper arm is mounted with silicone screw to avoid pricking the surface of bag.

- EPC device to control the edge position for varying web width.

- Union Special sewing head is available for customers’ request.

- New designed over tape and easy open device gives the convenience of opening of the bag mouth.

- With colorful operator-friendly human machine interface (HMI) offers English, Spain, Russia, Arabic, Chinese, French to access the machine operation easily.

- The conveyor stacker helps collect bag evenly and auto. counting in every stack.

Inline Edge Rotating & Gusseting Device

Punching Device

Micro-Perforation Device

Double Stitching Device

Human-Machine Interface control

Easy open device

Punch / Double Stitching

Easy Open